Mining Industry

Open-cast operations

We fine-tune models to reflect the unique geotechnical conditions of surface mining environments.

Mining Industry

DeepMatrix transforms fragmented mine operations into a unified intelligence layer, integrating geological data, equipment tracking, ore grade analysis, drone inspections, and regulatory compliance through bespoke AI analytics built for mining precision.

Connect With Us

Modern mines generate vast volumes of operational data, but without intelligent integration, its potential remains underutilized. DeepMatrix converts this complexity into real-time decisions, driving productivity, safety, and regulatory precision.

Strategic efficiency, compliance confidence, and faster decisions, made measurable through AI-powered mining intelligence.

DeepMatrix optimizes haulage timing and resource alignment across the pit-to-plant chain. Real-time visibility and AI-led planning translate into 15–30% gains in daily production output.

AI-powered reconciliation ensures sampled grades and dispatch volumes stay aligned. Mines using DeepMatrix have seen up to 22% improvement in grade tracking and loss prevention.

From drone visuals to sample records, DeepMatrix centralizes and auto-tags compliance data. Every log is traceable, time-stamped, and audit-ready across internal and regulatory checkpoints.

DeepMatrix monitors terrain, fatigue, and hazardous zones in real time, enabling mines to reduce high-risk incidents by 40% through predictive flagging and automated risk alerts.

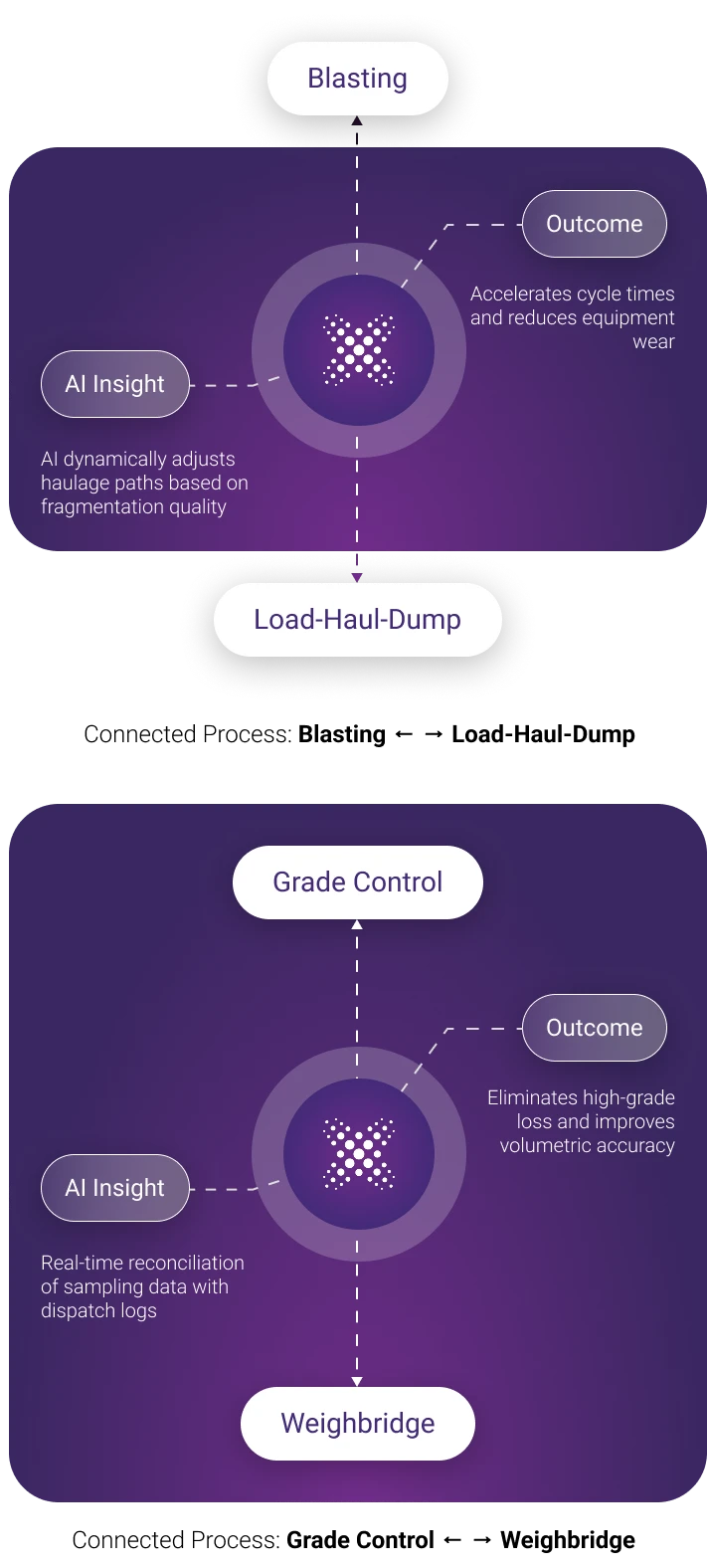

From drilling to dispatch, DeepMatrix links every phase of mining operations through real-time AI automation. By aligning processes that were once siloed, we drive faster decisions, fewer delays, and measurable improvements across the entire value chain.

Every mine is different, geology, fleet size, compliance pressure, or production goals. That’s why DeepMatrix doesn’t sell a fixed product. We co-create adaptive, AI-powered mining workflows matched to your exact environment.

We fine-tune models to reflect the unique geotechnical conditions of surface mining environments.

Aligning with institutional protocols or private efficiency standards, we support both operational modes.

Our platform works with aerial data or fully ground-based input, ensuring no data blind spots.

Seamless integrations that bring intelligence to your existing tech stack, without the need to replace it.

Let’s schedule a walkthrough tailored to your mine terrain, lifecycle stages, and operational risk workflows.

Get In Touch

Mining Industry

Modern mines generate vast volumes of operational data, but without intelligent integration, its potential remains underutilized. DeepMatrix converts this complexity into real-time decisions, driving productivity, safety, and regulatory precision.

Process

Impact on Production

Impact on Safety

Strategic efficiency, compliance confidence, and faster decisions, made measurable through AI-powered mining intelligence.

DeepMatrix optimizes haulage timing and resource alignment across the pit-to-plant chain. Real-time visibility and AI-led planning translate into 15–30% gains in daily production output.

AI-powered reconciliation ensures sampled grades and dispatch volumes stay aligned. Mines using DeepMatrix have seen up to 22% improvement in grade tracking and loss prevention.

From drone visuals to sample records, DeepMatrix centralizes and auto-tags compliance data. Every log is traceable, time-stamped, and audit-ready across internal and regulatory checkpoints.

DeepMatrix monitors terrain, fatigue, and hazardous zones in real time, enabling mines to reduce high-risk incidents by 40% through predictive flagging and automated risk alerts.

From drilling to dispatch, DeepMatrix links every phase of mining operations through real-time AI automation. By aligning processes that were once siloed, we drive faster decisions, fewer delays, and measurable improvements across the entire value chain.

Every mine is different, geology, fleet size, compliance pressure, or production goals. That’s why DeepMatrix doesn’t sell a fixed product. We co-create adaptive, AI-powered mining workflows matched to your exact environment.

We fine-tune models to reflect the unique geotechnical conditions of surface mining environments.

Our platform works with aerial data or fully ground-based input, ensuring no data blind spots.

Aligning with institutional protocols or private efficiency standards — we support both operational modes.

Seamless integrations that bring intelligence to your existing tech stack, without the need to replace it.

Deploy targeted AI for ore reconciliation, cycle time tuning, slope monitoring, fleet dispatch, and ESG compliance.

From remote standalone pits to coordinated networks across 100+ locations, scale is built in.

Let’s schedule a walkthrough tailored to your mine terrain, lifecycle stages, and operational risk workflows.

Get In Touch

We’ll walk you through use cases relevant to your industry.